Copyright © 2025 MEGA OILFIELD SERVICES SDN BHD. All rights reserved.

Web designed and maintained by Unison Systems

Pipe displacement (due to vibration & temperature cycles) over the support can damage the coating and in combination with water and dirt, corrosion can occur at the inaccessible area. Our method provides a reliable result about the condition of the pipe at the support.

To examine possible cracks in the ring grove of the ring-joint flanges.

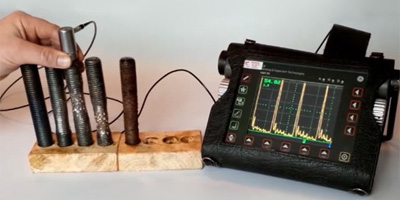

Inside the flange holes a bolt can start to corrode and loose its thickness, with this corrosion being visible from the outside. By means of ultrasonic testing, we are able to test the bolts, without loosening them.

In service corrosion at pipe supports had been an area of concern in a lot of industry, oil & gas being on of them. Visual inspection can provide an indication of corrosion (e.g. product build up, rust staining etc) but is hampered by the lack of access to the critical areas. This has lead to increased interest in the use of NDT methods for inspecting corrosion underneath pipe supports, in addition to conventional visual inspection.

The main aim of this inspection was to assess how accurately different NDT inspection techniques could detect and measure the remaining wall thickness of corrosion under the pipe supports.

This common form of outside corrosion occurs, when pipeline are lying on steel or concrete, or are hanging in clamps. Because of temperature changes, vibration etc, the piping is moving over the support which can cause damaging of the coating of the piping. In combination with water, corrosion will occur, even more when the facility is in a marine environment.

The inspection is based on ultrasonic testing and the principle is:

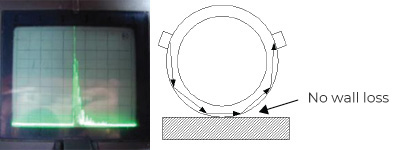

An emitting probe sends a sound beam through the material and the receiving probe captures it.

UT signal will be visible on the screen of the UT equipment and is adjusted to certain screen height as below.

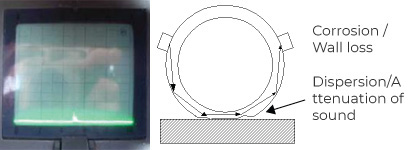

If there is a loss of wall thickness, the sound beam will be dispersed and less sound will be captured hence lowering the UT signal on the screen as below.

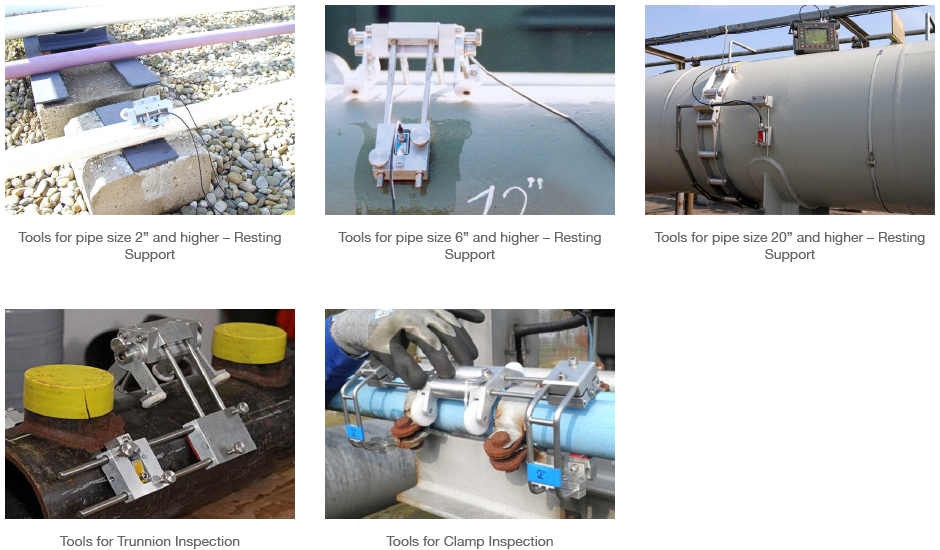

When investigating supports, sound beam is sent in circumferential direction of the pipe while sound beam in longitudinal direction is used for investigation on pipe clamps. Different set-ups are used for various configuration and inspection of pipe supports.

Inspection can be made until a surface temperature of 60°C. It is possible to inspect pipes with diameters from 2" and above, when the pipe is lying of supports (depending on surface condition and permeability of the coating).